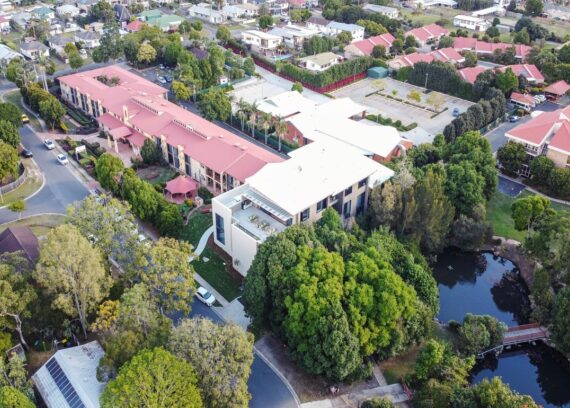

Kane Constructions were engaged under a Design & Construct contract to deliver the Bolton Clarke Moreton Shores Central Facilities & 60 Bed Aged Care Extension project within the existing Moreton Shores facility.

Together with the new building, the project incorporates 32 additional on-grade car spaces, with a terrace building which adjoins the existing facility, including a new building entry, reception and function spaces. In addition, Kane partially demolished the existing D Wing area to create a new laundry facility, sitting room, an extension to the existing cleaner’s room and relocation of the pan room.

Initially, Kane worked alongside Architectus and Calibre Consulting, together with Bolton Clarke during the ECI phase to value manage the design, in order to achieve the desired outcomes.

Kane provided buildability input to refine elements of the design, initially advising on some alternative selections such as external glazing, roof and façade options, and alternative sanitary fixtures and finishes. Kane worked closely with the consultants to offer an alternate methodology for the new car park, entry and bus turning facilities which removed sheet piling, all resulting in significant savings for Bolton Clarke. In addition, Kane installed Queensland’s first Legioguard warm water circulation system to provide substantial lifecycle savings for Bolton Clarke.

Kane provided various forms of cost and program savings throughout the duration of the works. Some of these alternatives included working with the client to provide a glazed pool fence system for residents to look out over the lake, however, given the cost was too high, Kane provided an alternative solution, utilising a combination of pool fence panel and glazed pool fencing to meet their budget and design intent.

The client requested the installation of a patient hoist system late in the project, and Kane was able to facilitate the installation of the ceiling track system without much impact on time or cost for the client. Another innovative solution Kane proposed was a conform platform, certified, pre-fabricated roof platform system. Originally this was designed to be aluminium perforated metal. Given the alternative solution utilised, Kane were able to save the client cost and time.